ABOUT US

GETTING TO KNOW VARVAR

VARVAR IS A JEWELRY COMPANY THAT HAS BEEN MANUFACTURING JEWELRY SINCE 2015. WE ARE LOCATED IN KYIV, UKRAINE. UNTIL 2020, THE COMPANY OPERATED UNDER THE VIKING WORKSHOP BRAND. THE COMPANY PROVIDES THRILLING CRAFTSMANSHIP AND EMPLOYS ONLY THE BEST JEWELERS IN UKRAINE. OUR OWN DESIGN DEPARTMENT CREATES AND IMPLEMENTS THE NEWEST TRENDS IN JEWELRY DESIGN.

Established - 1995

WE OFFER ONLY INNOVATIVE MODELS AND DESIGNS THAT FULLY MEET NEW TRENDS AND THE CURRENT WORLD FASHION STYLES.

THE MAIN TASK FOR US IS THE EXCEPTIONAL QUALITY OF JEWELRY AND CUSTOMER SATISFACTION.

WE PRODUCE 3’000+ OF JEWELRY PER MONTH. SINCE 2015, WE HAVE CREATED 1’000+ DIFFERENT JEWELRY DESIGNS AND RECEIVED 3’000+ POSITIVE REVIEWS FROM OUR CUSTOMERS.

EXCEPTIONAL CRAFTSMANSHIP

WE USE 925 (STERLING) SILVER, GOLD (YELLOW, WHITE, ROSE, 14K AND 18K), PLATINUM AND BRONZE TO CREATE JEWELRY. VARVAR PROVIDES THE FULL CYCLE OF JEWELRY PRODUCTION: FROM THE FIRST SKETCH OF THE FUTURE ITEMS TO THE PACKAGING OF THE FINISHED JEWEL IN A BRANDED BOX. ALSO VARVAR CREATES JEWELRY WITH PRECIOUS AND SEMI PRECIOUS GEMS LIKE AMETHYSTS, CITRINE DIAMONDS, EMERALDS, RUBIES, SAPPHIRES, ETC. HERE AT VARVAR, WE BUY GEMSTONES ONLY FROM THE MINING JEWELRY COMPANIES. ALL STONES ARE TESTED FOR QUALITY, BEAUTY, AND DURABILITY.

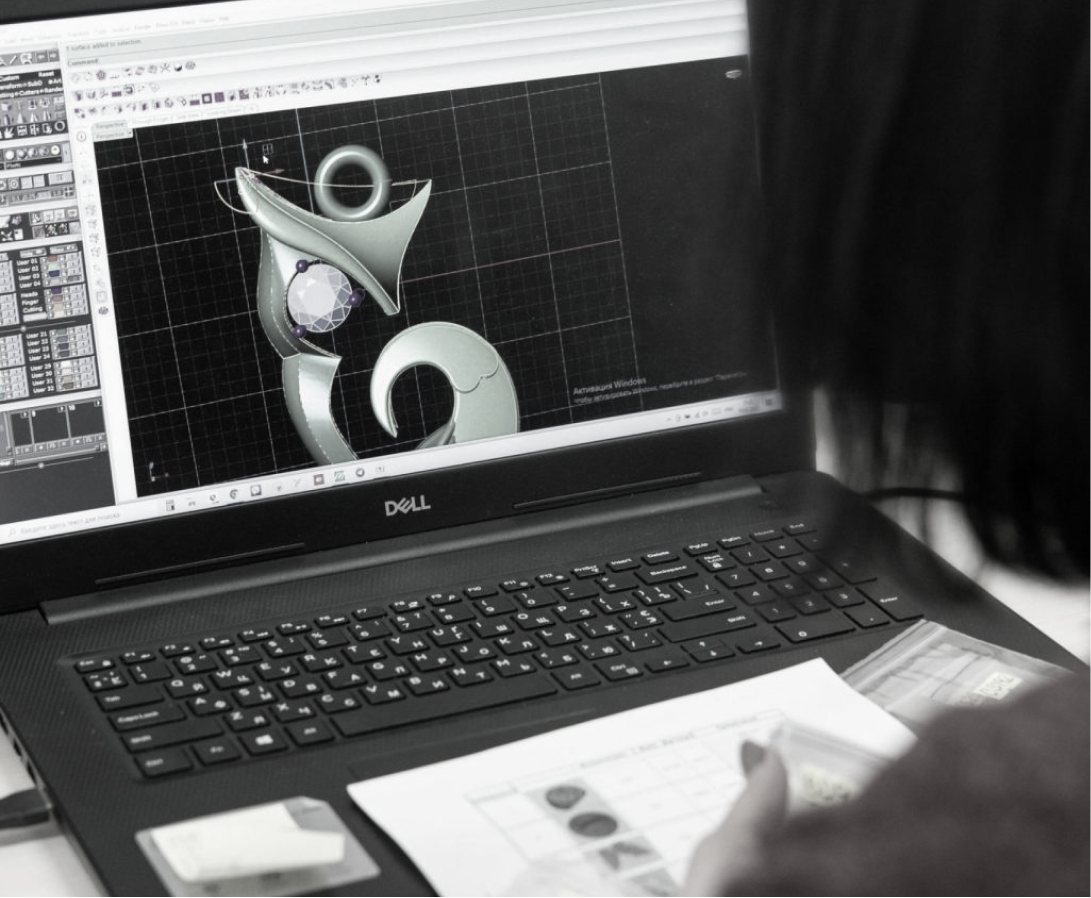

PROCESS OF JEWELRY CREATION

- first we make design:

- sketch - the designer draws the first sketch of the future jewelry on paper;

- 3d model - a specialist creates a 3d model of the item in a graphics editor on a computer;

- plastic prototype - items can be crafted using milling - to make simple ornaments, or 3d printing for more complex ones.

DIFFERENT JEWELRY TYPES

CURRENTLY, THE BRAND'S LINEUP HAS 10 COLLECTIONS, AND WE ARE PLANNING TO EXPAND THE LINE. THE MAIN COLLECTIONS ARE VIKING, EGYPTIAN, CLASSIC, MASONIC, ETC. WE CREATE RINGS, PENDANTS, CUFFLINKS, CHAINS, BRACELETS, BEADS AND CUSTOM DESIGNED JEWELRY. PROCESS OF

JEWELRY PROCESSING:

- primary processing. removing extra pieces of metal from the jewelry.

- grinding. the jewelry is grinding to make it smooth.

- soldering. sometimes a piece of jewelry consists of several parts. then the assembler melts the metal and joins the pieces together.

- blackening. the metal needs to be blackened to make every detail eye-catching. the jewelry is grinding again to become silvery black, which makes the details stand out.

- polishing. for a mesmerizing shine, craftsmen polish almost finished jewelry.

- adding a stone. the final stage is when gemstones are inserted into the jewelry.

WHY DOES VARVAR JEWELRY CHANGE THE PERCEPTION OF BEAUTY?

AT THE BEGINNING OF OUR JOURNEY, WE WANTED TO CREATE JEWELRY FOR A NARROW RANGE OF INTERESTS. THEREFORE, WE HAVE CREATED THE VIKING, EGYPTIAN, MARINE, MASONIC, BIKER COLLECTIONS AND OTHERS.

IN THESE COLLECTIONS, EACH DETAIL HAS ITS OWN HIDDEN MEANING AND CARRIES IT TO THE MASSES, REPRODUCING A CERTAIN ORNAMENT OR SYMBOL.

IF EARLIER WE AIMED TO CREATE THEMATIC JEWELRY, NOW WE ARE LOOKING TOWARDS THE TRENDS OF CLASSIC JEWELRY FOR WOMEN AND MEN ALL OVER THE WORLD. WE ARE CONVINCED THAT THANKS TO BARBAR JEWELRY, EVERYONE WILL FEEL LIKE A SUPERSTAR.